Fuselage of Aircraft

Fuselage is a body of an aircraft to which the wings, tail and Landing Gear units are attached. Spaces from the cockpit cabin, Passenger cabin, Cargo, Controls unit are located inside the fuselage. Design and size of the fuselage varies according to the function to the aircraft. The word fuselage comes from a French word “fusele” means “splindle-shape” Fuselage is a long and vertical spindle hollow tube. The hollow shape design provides maximum strength with minimum weight.

Fuselage are designed to satisfy two major criteria:

- Protect the passengers in the event of crash.

- Efficient in fitting together the wing, tail, landing gear and other control surface in perfect place accomplished with interior space for passenger comfort with minimum frontal area to contour drag for maximum performance.

Fuse large must have a point of attachment for each part such as wings, tail, Landing Gear and Engines to arrange and installed. So that at time of emergency this part can be inspected, removed, repaired and replaced again easily. The fuselage must be very strong at the point of attachment as more loads would be acting on the fuselage and fitted parts during flying and landing.

Outer Design Criteria of Fuselage

Fuselage is the outer shell of the aircraft, the cabin inside are fully pressurized and the pressure inside the aircraft is greater than the pressure outside due to which the fuselage is exposed to different stress, It must be designed with strong durable material. If were any pressure loss occurs. Oxygen levels will drop it can create a dangerous environment to the crew and the passenger inside.

During the time of rotation of the aircraft more torque will be produce fuselage should be designed to withstand this torque force which leads to collapse of the entire structure, as more load will be acting on the outer surface of Fuse large.

Fuselage design base on Aircraft Usage

In fighter jet have a slender and streamline fuselage to contour drag for maximum performance and cockpit will only cabin space present large enough only for the controls and pilot. Cockpit is place on the top of the fuselage for ground visualization and the engines and fuel are place at the rear of the fuselage.

In airlines Civil aircraft use to have a wide, long fuselage carry the many number of passenger as well as cargo. The cockpit will have large space and separate desk for passenger cabin and cargo, Cargo space will be located below the passenger cabin and fuel is stored at the wing.

In single engine aircraft the engine is mounted in nose of the fuselage. Cockpit will be place at the top to provide ground visibility.

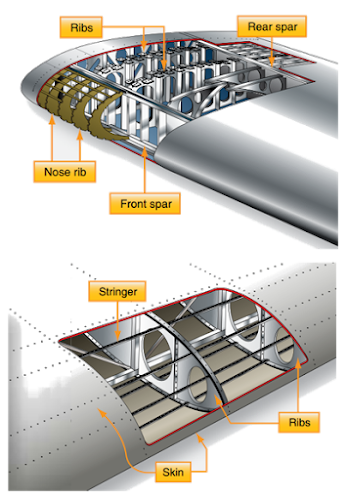

Fuselage skeleton and skin

Fuselage shielded by a thin sheet of material stiffened by large number of longitudinal stringers running together with transverse frames place between, they carry bending moment, shear force and torsional load which causes axial stresses in the stringers and skin. As shear stress acts on the skin because of the resistance stringers the shear force gets ignored.

(Shear Force: Force acting perpendicular to its longitudinal axis)

Distance between adjacent stringer is usually small due which shear flow in the connecting panel is small.

Material Used

Most airplane uses an Aluminium Fuselage, As Aluminium is strong, corrosive resist to rust and light weight. This characters makes aluminium effect used material for making aircraft component which includes fuselage.

For more Related Topic and Information on Aircraft Technology - CLICK HERE